A comprehensive solution for automation and digitisation of production of concentrates, fruit and vegetable juices.

A comprehensive solution for automation and digitisation of production of concentrates, fruit and vegetable juices.

Implementing the Industry 4.0 concept in companies producing fruit and vegetable concentrates has never been so simple.

JUICE 4.0 allows the process of automation and complete digitisation of the juice production process to be conducted, and production lines, plants and processing concerns having multiple branches depending on the enterprise size to be integrated into a single system at the level of machinery.

The integrated system comprises automation of presses and software for production process supervision, an IoT platform for monitoring costs of utilities and managing efficiency in distributed plants, as well as machine learning algorithms designed for production optimisation. Each of the components of the comprehensive offer JUICE 4.0 can be implemented separately or jointly, which allows the digital transformation process of a processing enterprise to be flexibly planned out.

The Industry 4.0 concept is implemented by combining automation with digitisation in order to increase the competitiveness of an enterprise in the market. JUICE 4.0 addresses this concept by offering a set of dedicated solutions for the digital transformation of enterprises processing fruits and vegetables.

JUICE 4.0 allows also the enterprises operating older presses, in particular the HP5000 (Bucher) presses, which have been successfully in operation for many years, to go through a complete transformation process, and to convert these presses into fully automated and metered equipment supported by modern control algorithms and advanced analytics. Significantly, modernised presses achieve a comparable, and even higher productivity over time and a higher yield from a set pulp unit as the most modern presses in the market, at a better price, and combined with a cloud IoT platform they allow the additional competitive edge to be achieved.

Apart from necessary modernisations of control systems and automation of the existing presses, the JUICE 4.0 solution is fitted with algorithms optimising utility consumption in the production process and can be expanded by metering with IoT devices for such utilities as electricity, water, gas in the entire production cycle, so that the system can compute costs of utilities per litre of produced concentrate.

The integration with an ERP system as regards information about input purchase costs and purchase costs of individual utilities is the final stage of the digitisation process. Combined with machine learning algorithms, it allows the process to be optimally conducted by adjusting the number of press operation cycles to the set parameters.

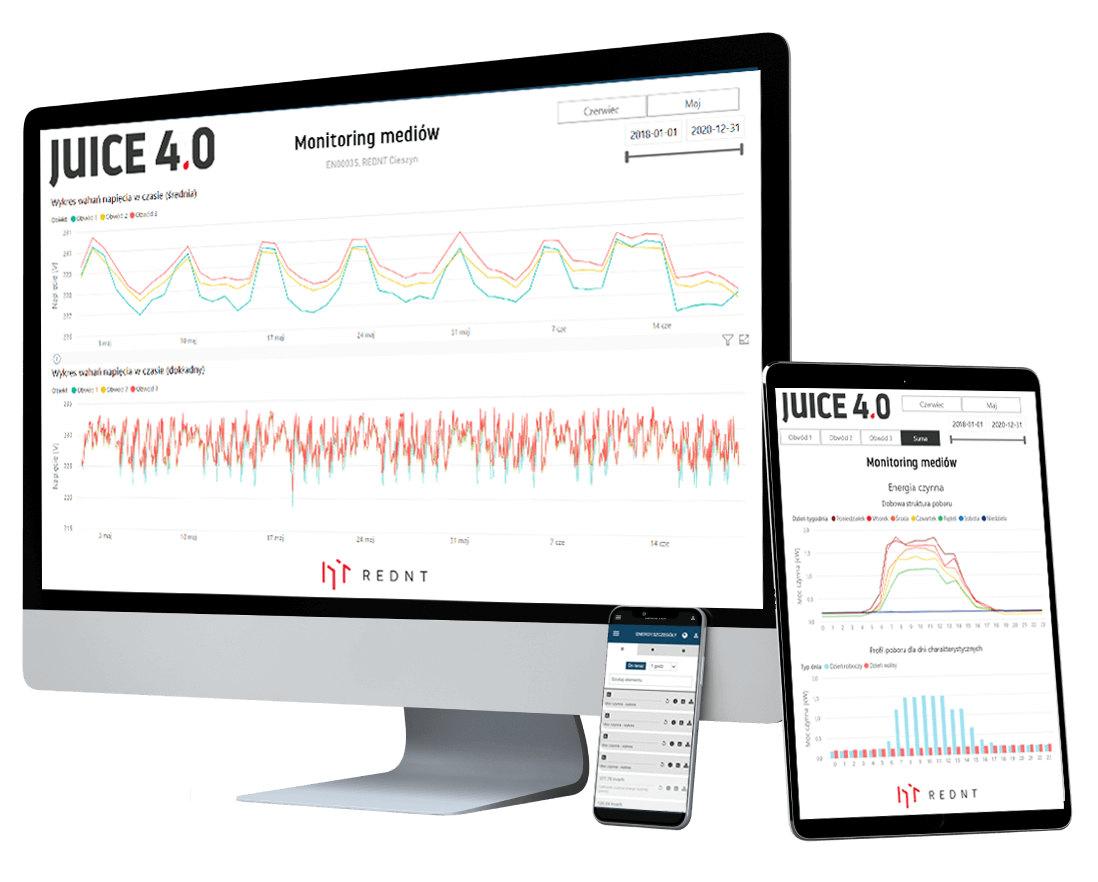

JUICE 4.0 is a perfect platform integrating production data from many distributed plants, thanks to a cloud solution accessible via a browser and a mobile application. Any time, the group management can verify the availability and efficiency of machinery, compare costs of utilities per litre of produced concentrate or check inventory in individual plants — everything to make better business decisions.

Carry out a digital transformation of your concentrate production process by introducing automation, advanced control algorithms and the IoT technology and machine learning, and make better business decisions thanks to the aggregation of information from multiple plants at a group headquarters level.

The advanced control algorithm increases the total production by even 20% compared to the manual control, by expediting and ustreamlining the process and increasing the yield of the set pulp

Reduce utility consumption (electricity, water, gas) even by 10% and at the same time monitor utility consumption per produced concentrate litre

Use AI advanced algorithms to generate tips for operators on how to optimally manage a process and increase productivity even by 7%

Compare production costs, press efficiency, yield, utility costs per concentrate litre or collected in distributed production plants on-line and make better business decisions

Thanks to the full process automation achieve even threefold reduction of process operating costs

JUICE 4.0 allows the process automation and digitisation of the concentrate production process to be gradually executed depending on the current level of technology of a specific production company, and the company size itself. From the press modernisation through the IoT platform to the full integration with business tools, the ERP system and machine learning algorithms.

Full process automation

Smart IoT metering

Advanced control algorithms

Dedicated recipes

Local HMI panels

The SCADA system for supervision and remote control

Access to data from any place via the Web application

Mobile application (iOS, Android)

Integration with Microsoft Power BI

Integracja z Microsoft Sharepoint

Integration with Microsoft Teams

Integration with ERP

Machine learning algorithms

TLS 1.2 for the purposes of communication encoding

Microsoft Active Directory for authorisation and authentication

Thanks to taking over AMPER-POL, REDNT S.A. (the producer of JUICE 4.0) has acquired 20 years of experience in automation and modernisation of juice presses made home and abroad for many processing plants. Below find a list of customers, for which AMPER-POL or, already after the takeover, REDNT S.A. has provided services in automation, press modernisation or digitising industrial processes.